Electronic Materials

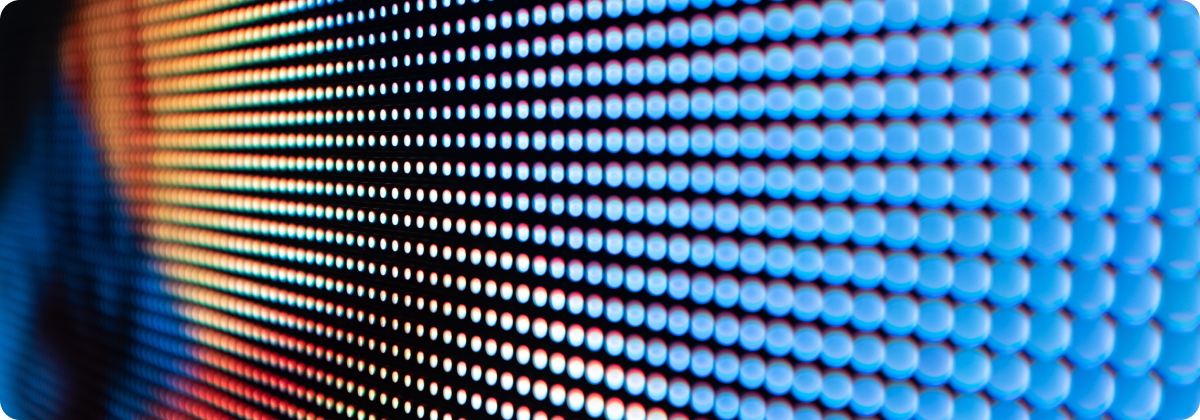

Digital innovation begins with electronic materials built with ‘super-gap’ technology

In 1994, SAMSUNG SDI took the first step into electronic material business

with development of EMC, an encapsulant for the semiconductor.

Our market-leading portfolio encompasses patterning materials that enable

highly-integrated and micro processing and packaging materials, as well as

organic materials and films that implement high resolutions and diversified

form factors in smartphones.

Leveraging unrivalled technological competitiveness and top quality we

have acquired through such vigorous endeavors, SAMSUNG SDI bids to grow

its presence in the market for separators, one of core battery materials.

This will complete SAMSUNG SDI’s holistic range of business that contributes

to digital transformation.

Application

Semiconductor materials for functionality and quality

SAMSUNG SDI leverages its expertise in organic and inorganic materials design so as to provide materials solutions for a semiconductor business that requires high-performing and highly integrated memory and process chips for cutting-edge devices, e.g. mobile phones and laptops. A race to reduce nanometers in semiconductor chips is revealing impurities and defects that have been avoiding detection before. SAMSUNG SDI’s superb technology in refining and defect control helps eliminate such defects. Stability of a device is more vital than ever as semiconductor device functions keep stacking. SAMSUNG SDI’s exceptional competence in composition design and reliability assurance technology makes it possible to bring forth differentiated packaging solutions that protect semiconductor devices from external impact, moisture, or damage, ensuring stable performance of the semiconductor devices.

Spin On Hardmask (SOH)

SOH is a coating material used to form micro-patterns in the semiconductor. With rigidity and selection ratio, SOH has deep etching capability. SAMSUNG SDI makes SOH products that replaced the conventional chemical vapor deposition (CVD) process with the spin-coating process, which enabled process streamlining, productivity improvement, and cost reduction – a holistic contribution to advancing semiconductor process technologies.

Spin On Dielectrics (SOD)

SOD is a coating material that insulates between transistors or layers, serving to prevent voids between micro-patterns as it has low reactivity. SAMSUNG SDI applied the spin-coating process to its SOD, departing from the conventional CVD process, which enabled process streamlining, productivity improvement, and cost reduction – a holistic contribution to advancing semiconductor process technologies.

Chemical Mechanical

Planarization (CMP) Slurry

CMP slurry is an abrasive which is used to smoothen the surface of wafers in a chemical and mechanical mechanism, enabling higher planarization and lower defect rate. SAMSUNG SDI’s CMP slurry portfolio consists of oxide slurry, metal (W, Cu) slurry, ceria slurry.

Extreme Ultra Violet (EUV) Materials

EUV materials enable an ultra-micro EUV wavelength of 13.5 nanometers in semiconductor patterns. SAMSUNG SDI is developing and mass-producing photoresists, under-layers and thinners through proprietary patents and joint evaluation.

CMOS Image Sensor Color Resist (CIS-CR)

CIS-CR materials are photoresists that implement pixel colors in CMOS image sensors working as RGB color processing filters. SAMSUNG SDI’s CIS-CR materials enable micro-patterning that achieves high resolution and high color fidelity while minimizing pixel color crosstalk.

EMC (Epoxy Molding Compound)

EMC is a thermoset molding compound that protects semiconductor devices from external environments such as moisture and impact and effectively dissipates heat arising from operating chips. SAMSUNG SDI provides EMC materials for DRAM, NAND, and foundry applications that meet rising standards of semiconductor packaging becoming lighter and thinner.

PID (Photo Imageable Dielectric)

PID is a photosensitive patterning insulator, part of insulation layers in metal interconnects of a next-generation semiconductor packaging structure. PID features high resolution and high reliability in heat resistance and chemical resistance. SAMSUNG SDI customizes PID products to suit each varying need of customers.

Display materials for even higher resolution and diverse form factors

A booming trend of people enjoying big-size contents such as live streaming and gaming means that displays are consuming more electricity. SAMSUNG SDI endeavors to develop new materials and optical designs that implement high efficiency and transmittance in the materials, reducing power consumption of display products. With superior materials and physical property designs, SAMSUNG SDI takes pride in supplying only the most superb materials featuring excellent viewing angles, contrast ratios, and purity. Display panels built with these materials come out with the highest resolution. Rich data base and technology expertise of SAMSUNG SDI serves to broaden the spectrum of form factors of its display products from market-proven flexible displays and foldable displays to slidable and rollable displays.

Polarizer Film

Polarizing film is a thin, black layer on display panels and is one of the core display elements as it adjusts how light passes and reflects on LCD and OLED panels. SAMSUNG SDI’s polarizer films boast excellent features and are built into premium TV lineups by Samsung Electronics.

Foldable Optical Clear Adhesive (FOCA)

FOCA tapes are used to bond panels, devices and screen displays for foldable phones. SAMSUNG SDI became the first to mass-produce FOCA in the world which have been supplied for Galaxy Z Fold and Galaxy Z Flip products by Samsung Electronics. SAMSUNG SDI holds proprietary core FOCA technologies patented home and abroad and provides customized solutions that accommodate diverse needs of panel structures.

Protective Film for OLED Processing

OLED processing protective films are used in the process of manufacturing flexible OLED panels. The low adhesiveness creates little residue leaving the surface clean. SAMSUNG SDI’s products feature high reliability and stickiness that prevents contamination when removed.

Organic Light Emitting Diodes (OLED) Materials

In OLED, electrons flowing to the cathode and holes injected at the anode encounter on the light-emitting layer to allow light escape. SAMSUNG SDI enable high-level features and top quality in its green-host, p-dopant, ETL materials that are applied to OLED-based mobile phones and TVs.

Thin Film Encapsulation (TFE)

TFE is an encapsulant that protects OLED devices from external environments like moisture and oxygen. A flexible OLED panel is comprised of organic (TFE) and inorganic (SiNx) layers. SAMSUNG SDI supplies TFE materials for majority of panel makers all over the world.

QD (Quantum Dot) Ink

QD ink materials convert blue light from QD-display backlight into a perfectly optimized red, and green spectrum using QD particles. SAMSUNG SDI’s QD ink materials have high color-conversion efficiency enabled by optimized QD particle characteristics.

Battery materials for safer batteries

SAMSUNG SDI draws on its cumulative technologies in materials design in order to develop optimal materials that allow not only better heat resistance and strength but also a higher level of safety for batteries.

We have fully internalized technology for coating separators that ensure battery’s stability. Leveraging such differentiated technological edge, SAMSUNG SDI produces heat-resistant adhesive separators for more thermally stable, stronger, and higher-capacity batteries.

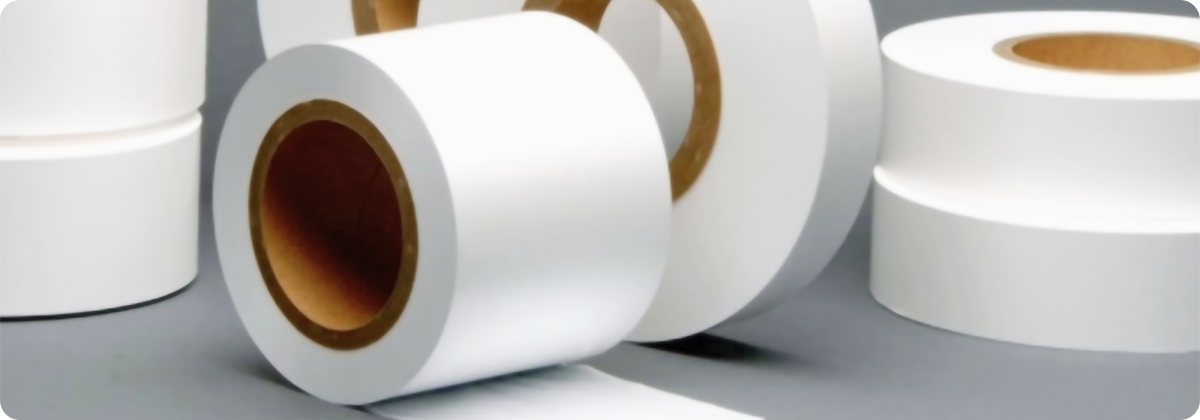

Separators

A separator lithium-ion batteries is a thin insulating membrane between the cathode and the anode that has submicron-sized pores on the surface. They are vital in preventing short-circuiting of two electrodes in lithium-ion batteries. Also serving as a path for lithium-ion transport, separators can materialize a lithium-ion battery’s high output by characterization of pore structures. SAMSUNG SDI manufactures separators with diverse coating structures fit for respective purposes. (CCS, MFS, MCS)

Browse through the world-class electronic materials of SAMSUNG SDI and make your inquiries for your business.